Changes to improve the design of products and production systems are essential for the survival and prosperity of manufacturing organizations. Mastering the development of flexible assembly systems with a holistic long-term view can enable generating value over their life cycles which is crucial for competitiveness.

Reasons to change in assembly include for example, the production of current product variety and preparation to the transition towards future new (radical) product generations like electrical and autonomous vehicles, integration of new technologies such as those connected to Industry 4.0, improvement of workplaces, compilation with internal and external environmental requirements, as well as providing specific customer solutions in global markets. Mastering the development of flexible assembly systems with a holistic long-term view can enable generating value over their life cycles which is crucial for competitiveness.

Design processes concern the way of working during the design to create new assembly system concepts and solutions that will be potentially realized becoming process innovations. The design process of flexible assembly systems is particularly challenging because flexibility involves other changeability concepts and also concerns several dimensions such as products, manufacturing technology, labor, material handling, and there are diversity of perspectives and interests.

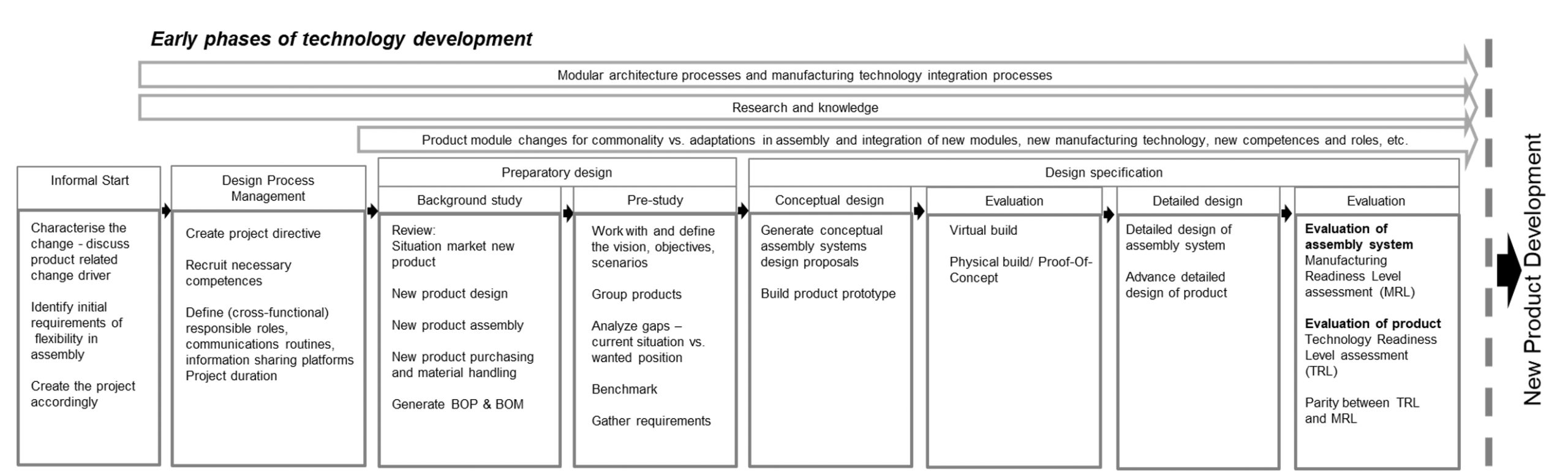

Allowing a holistic and timely consideration of flexibility

It has been argued that it is difficult to design desired levels of flexibility and quantitative information regarding flexibility is also required for decision-making. However, design work can be supported by improving working processes and procedures that consider flexibility in the assembly systems given the current need of established approaches and guidelines. Thus, further research is essential to understand the relation between design processes and flexibility.

Figure 1. Flexibility – oriented design process framework

(Simplified from the thesis)

To increase knowledge on how to achieve flexible assembly systems through design processes and contribute to the development of working procedures to support design processes of flexible assembly systems, this research focused on the study of factors involved in the design process and their influence to achieve flexibility outcomes. It is based on literature reviews and five case studies conducted in the manufacturing industry of heavy vehicles. Six papers are appended to this thesis.

A simplified version of a developed flexibility – oriented design process framework that integrates the findings of this research is presented in Figure 1. It emphasizes the need of start working with the design process of assembly systems already from the early innovative phases of technology development to allow a holistic and timely consideration of flexibility and reconfigurability in both products and assembly systems designs with a long-term view.

The framework also encourages the inclusion of diverse processes, roles, and functions within an organization in the design process, and highlights activities that facilitate the design process of flexible assembly systems. Even when the framework looks sequentially, some activities can be conducted in parallel and it is common some level of iteration. These working procedures can be used to support the work of those involved in designing flexible assembly systems.

By Natalia Svensson Harari

PhD from Mälardalen University